Tools, strategies and applications for integration of edge data into business systems are hot topics. How do you offload stress and computing resources from your network, enable more efficient data integration, and improve the efficiency of transactions and data transfer? How can you leverage computing resources where they will most effectively deliver results? The Industrial Internet of Things (IIoT) requires streamlined solutions to manage remote computing assets and maximize the benefit of the data they produce.

In this post, we will examine some IIoT data integration use case examples involving the Digi WR31 cellular router, which is a member of the Digi industrial router product line.

Introducing the Digi WR31 Industrial Router

The Digi WR31 is a best-in-class cellular router designed to meet the critical needs of industries like oil and gas and utilities – especially power. This heavy-duty device is built with extreme temperature tolerance, and possesses all of the features for security, remote management and reliability that customers expect from Digi hardware products.

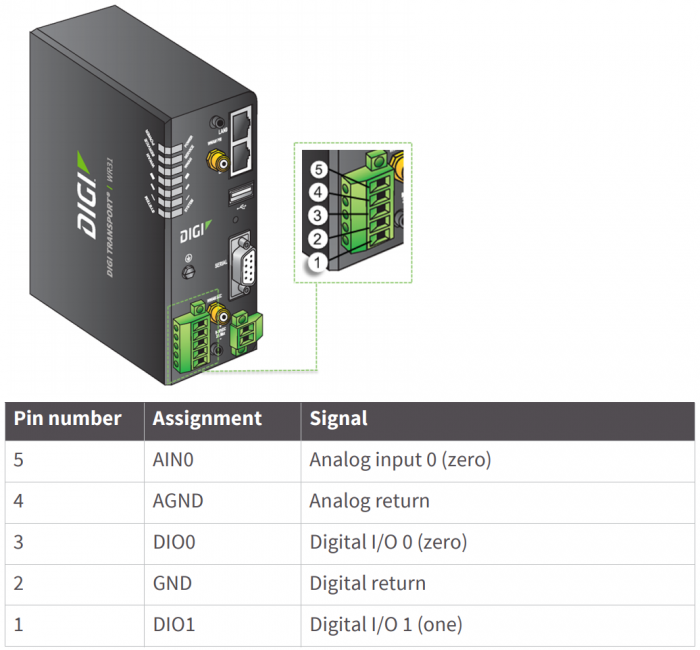

A key differentiator for the Digi WR31 is the presence of on-board General Purpose Input/Output (GPIO) in the form of two digital I/O interfaces and one analog input. GPIO allows users to accomplish tasks like taking readings from analog sensors and remotely executing on/off control to edge-connected equipment like pumps and generators.

Industrial IoT Use Cases for Edge Computing

Many Digi customers have highly demanding applications operating in extreme conditions such as mining and oil and gas, which are subject to a range of environmental conditions. Here are two such examples.

Oil and Gas Use Case

In this example, the customer is an oil and gas company that leverages the Digi WR31 on-board digital I/O. The companys application involves a private radio communications network.

The private radio network occasionally freezes and becomes unresponsive under certain circumstances, and the cost of sending a resource onsite to re-power the system is considerable. This customer has resolved the issue by placing Digi WR31 routers at each radio site and connecting an inline relay to the Digital output to interrupt/re-enable power to the private radio units. When a radio become unresponsive, the customer can now send a command to the Digital I/O on the Digi WR31, cutting all power from the private radio, then re-enabling it, resulting in a hard system reset. This solution avoids repeated truck rolls to numerous distant sites each year, resulting in considerable cost savings.

Power Company Use Case

Another customer example involves a major power utility that installs Digi WR31 routers throughout the smart grid, using the on-board serial connection to monitor reclosers (power grid circuit breakers) and maintain a high degree of power reliability for more than four million customers. The Digi WR31 is installed outdoors in a utility box that also contains a battery backup, so the customer leverages both digital interfaces on the WR31 as inputs to monitor two conditions:

- Utility box door opens or closes

- Router input power switches from line electricity to battery

Each time one of the above conditions is triggered or reset, the occurrence is denoted in a log file with a timestamp for further review and analysis by a company administrator. Condition detection and logging are achieved through the use of a simple Python program running directly on the router. The combination of an on-board programming environment and GPIO enable the customer to eliminate additional hardware while delivering a complete solution at the edge.

Connectivity to Cloud Applications in Industrial IoT

The oil and gas industry is currently undergoing a paradigm shift, with some of the largest players actively embracing hosted infrastructure such as Amazon's AWS platform and Microsoft Azure after years of reliance on on-premise solutions. This is occurring because the security and data residency models on those platforms now meet the needs of customers.

At the same time,

Digi Remote Manager® is becoming increasingly popular with these customers for similar reasons.

Along with its centralized device management capabilities, Digi Remote Manager (DRM) delivers a comprehensive Application Programming Interface (API), making it easy to integrate bi-directional device data into other platforms for a range of purposes. These can include:

- Triggering process workflow

- Sending commands to devices in the field

- Developing custom reports

Data can be externalized through both pull and push methods, allowing for virtually instantaneous rendering if desired.

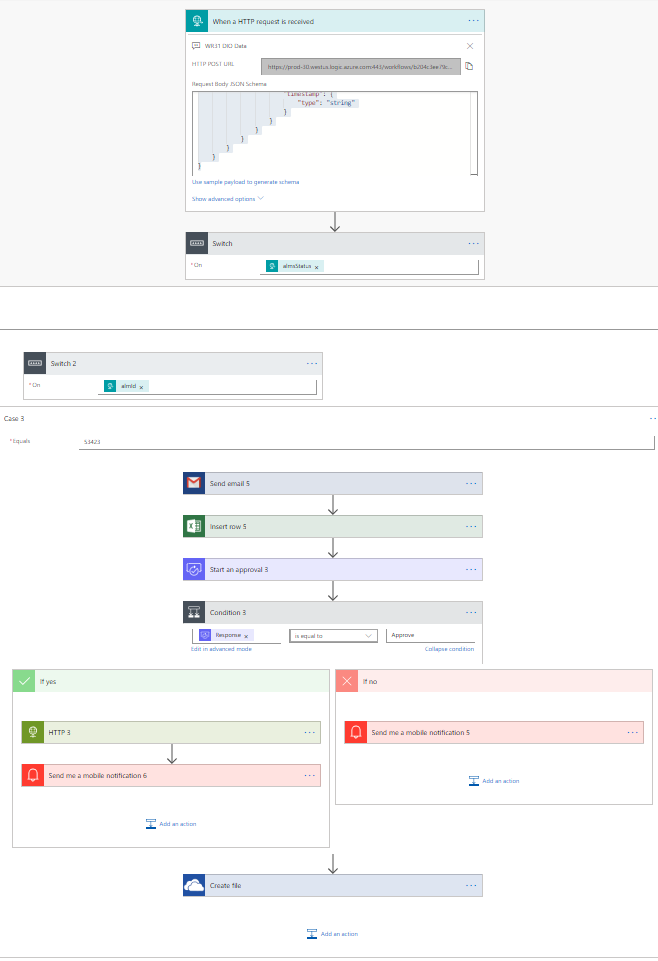

Digi Remote Manager and Microsoft Flow

The following is a partial example of DRM data integration with Microsoft Flow. This workflow leverages DRM's alarm engine in conjunction with the API's data push mechanism. Each time a device data alarm triggers for a specific DRM account, all of the alarm's pertinent information is sent to Microsoft Flow as a JSON payload, including Alarm ID, Alarm Status, DataStream triggering the alarm, and so on. Microsoft Flow then matches the Alarm ID to the corresponding action that must occur – including sending a command to a Digi WR31 to actuate GPIO:

In Summary

The availability of GPIO and a Python programming environment on-board the Digi WR31 allows the device to function much like a Remote Terminal Unit (RTU), while at the same time delivering the value of a truly industrial-grade cellular router with automatic dual-cellular failover capabilities.

Enhancing those capabilities through data externalization through use of the Digi Remote Manager API to platforms like AWS and Azure makes it possible for a small group or even a single person to develop powerful solutions more quickly and efficiently than an entire development team.

>> Contact us for help planning, developing and deploying your next IoT application.